We give you tools to turn your ideas

into reality!

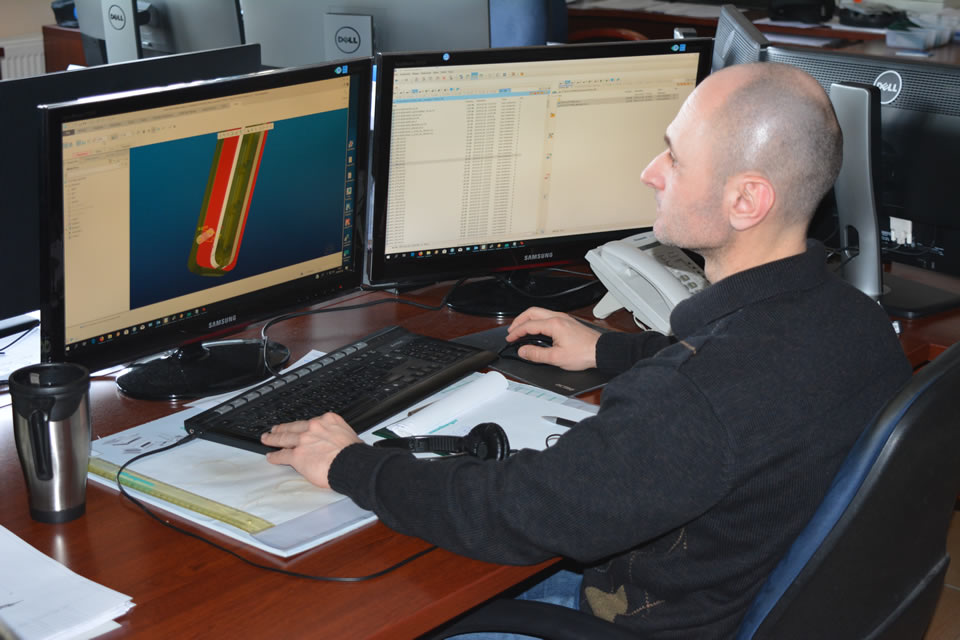

Professionalism in toolmaking

Our design engineers are using the most advanced software to design the tools and modeling the injection moulding process. Their wide range of experience give us more help to produce your product in serial production with excellent quality.

More information

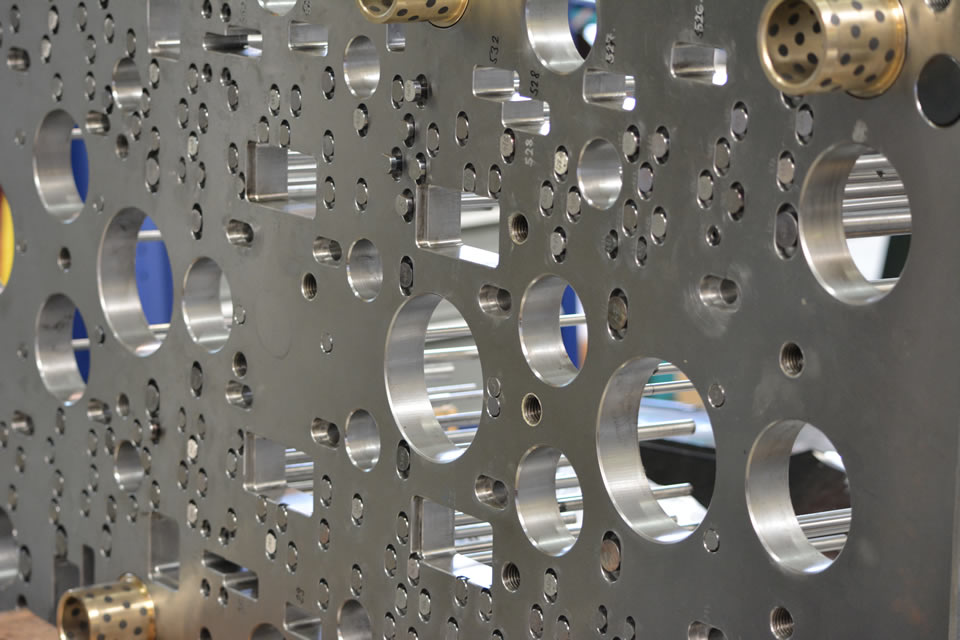

Toolmaking from high quality materials

The satisfied business partner is important for us. In every case the tools are made using of prime (Meusburger, Thyssenkrupp, Böhler, Hasco, Alfun, Amari) materials, to guarantee the long lifetime and expected quality by the customer.

More information

Tool maintenance and repair

Usage of the injection or blow moulding tools requires maintenance periodically, allowing the tool to serve you during the planned lifetime. We are available to our partners in case of repairs occurred from improper use or other reasons.

More informationAbout Us

PLASTIC-FORM Ltd. is one of the most known toolmaker in Hungary in point of injection and blow moulding tools. Most major elements of our portfolio are: designing and making of tools for automotive industry, technical plastics, household and packaging products.

The basis of our activity is provided by the highly qualified and experienced team of professionals who have been involved in tool manufacture for many years. As a supplier of manufacturers the plastic injected and blow moulded products PLASTIC-FORM Ltd. provides a full spectrum of services, from the designing of tools, through their manufacturing, maintenance right up to their servicing, as well as consultation.

Our colleagues are ready for the survey of your needs, design the perfect product, and tool construction, producing the best quality tool even with first tool trial additionally.

Why Choose Us?

Experience

More than 20 years of experience in toolmaking. Highly qualified and/or English, German speaking engineers.

Full service

We do not only produce the tool, but also based on your imagined product we will design, build and test it. With our own trucks we are able to deliver it to your location, and maintain it periodically by demands.

Planning

If the product does exist in your head, we make the 2D drawing and 3D model based on the agreed parameters.

Activities

From tool design to tool and component production, we provide a full range of services up to the delivery of the finished tool by our own truck.

Total tooling management

Tool design, tool manufacturing, tool trial: we manage the entire process of toolmaking.

Toolmaking and maintenance

Production of new tools, repair, modification and maintenance of existing ones.

Technologies

Our professional experience, trained engineers and optimal machine park guarantee success.

Engineering

work

Feasibility and manufacturability test based on 2D / 3D drawings, tool design, moulding simulation.

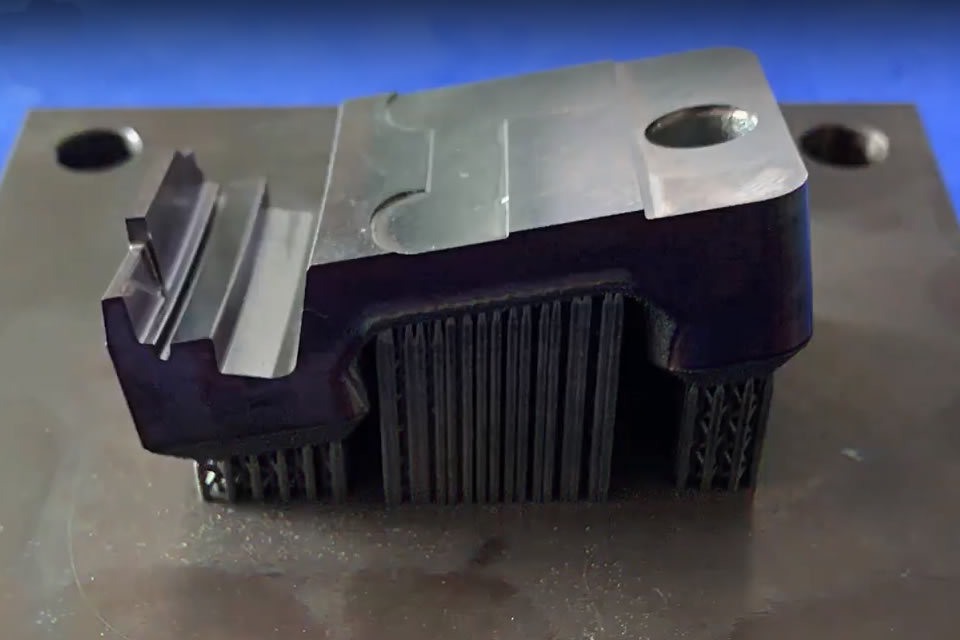

Read more3D

printing

Prototyping, custom and small series printing, injection moulding tool optimization with metal printing.

Read moreMachining

technologies

Conventional machining equipments, different CNC machining centers and laser welding equipment.

Read moreTool

assembly

Fitting and inspection of manufactured, maintained or repaired tool surfaces with a spotting press.

Read moreGallery

Our team

Our colleagues are happy to help

János Jobbágy

project manager

Dávid Nagy

project manager

Zoltán Gara

tool transportation

Enikő Burai

financial leaderOur clients

Contact

info@plasticform.hu